AGS INDUSTRIES

AGS INDUSTRIES, has continued to grow. From its humble beginnings to an international supplier of high quality products. To be the best global company for various pressure application products.

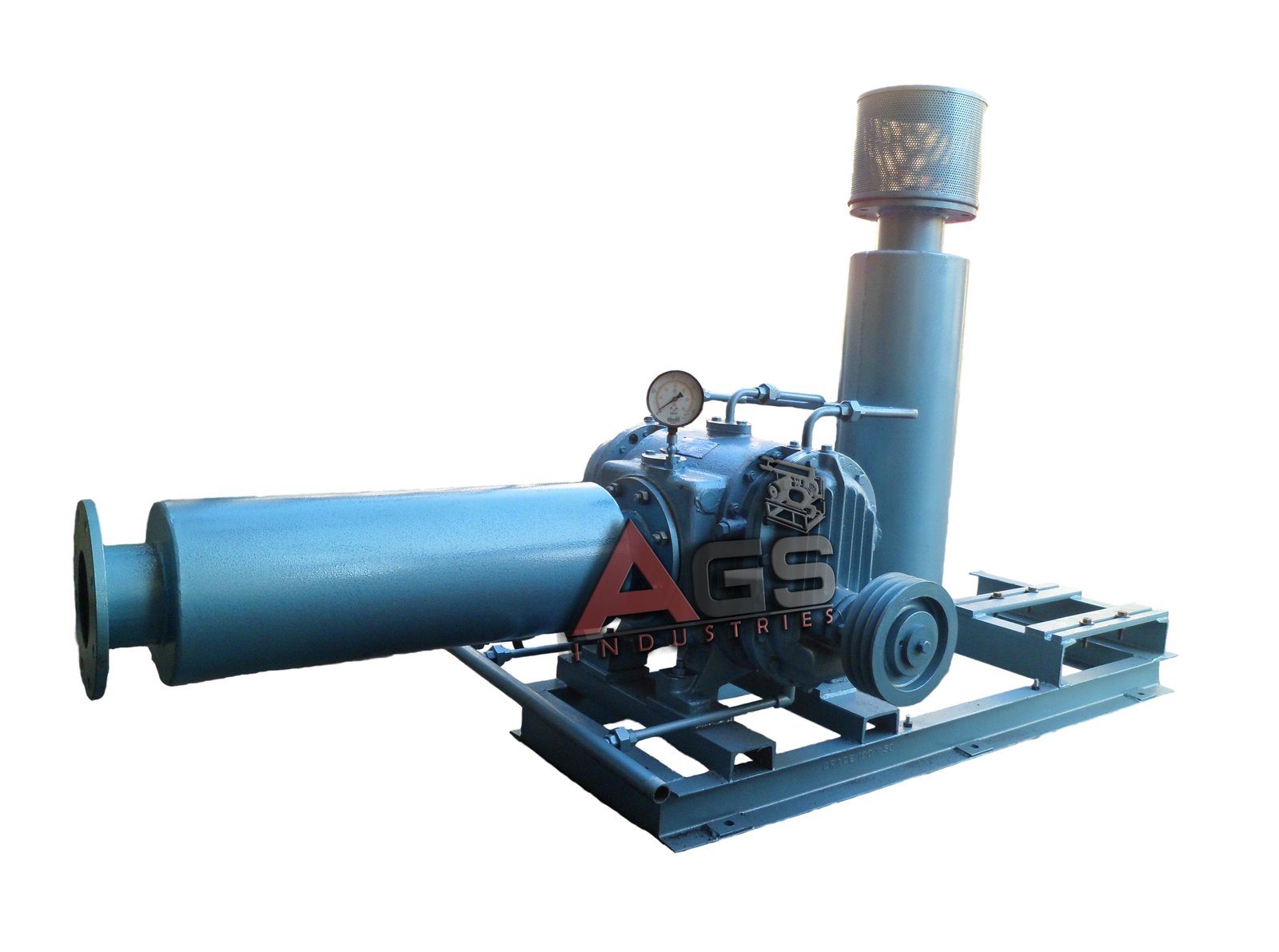

AGS Twin Lobe Compressors / Blowers are positive displacement units, whose pumping capacity is determined by size, operating speed and pressure conditions. It employs two Twin Lobe impellers mounted on parallel shafts, rotating in opposite direction within a casing closed at the ends by side covers. As the rotors rotate, air is drawn into one side of the casing and forced out of the opposite side against the existing pressures. The differential pressure developed, therefore, depends upon the resistance of the connected system. The Blowers, being positive displacement type, do not develop pressure within the casing but the discharge pressure depends upon the system resistance / back pressure. A pair of accurately machined cast, hardened and ground timing gears maintain clearances between the rotors, during rotation. The air, thus delivered, is 100% OIL FREE.

AGS water cooled blowers are continuous operation heavy duty units. Main body, Side Covers & Outer Covers are made out of graded ferrous casting. Gears are made out of alloy steel duly hardened, ground & nitrated. Rotors are machined on VMC profile for highest accuracy which result in consistency & performance. These heavy-duty blowers are designed for continuous service, with a special arrangement to prevent the rapid backflow of air in to the blower from the discharge area. This design reduce noise, vibration and horse power level over conventional blowers. The twin-lobe rotor profile ensures maximum volumetric efficiency with minimum power absorption. All AGS blowers units may operate under either vacuum or pressure application with no equipments modification. All ARP series are available with special seals for gas applications.

The System Specially Design & Developed By AGS For Conveying Cement & Fly Ash From Bulker To Silos As Medium Of Air. The Main Component Of System Is AGS Twin Lobe Air Blower Used For Generating Efficient Amount Of Air Mass And Develop Sufficient Pressure To Carry Out The Cement As Well As Fly Ash With Air From Bulker To Silos. This system is used for Unloading Cement From Bulker to Silo as well as Bulker to Godown. The System is Available in Various Models.

The System Specially Design & Developed By AGS is an ISO 9001-2015 company. We are premium quality equipment manufacturer and solution provider of cement feeding system. We offer packaged system for conveying/feeding Cement/Fly Ash into silos at Batching Plant sites. These silo feeding systems are synonymous with modern and efficient construction industry practices contributing to improvement in technique and efficiency. In order to fulfil industry requirements, our cement feeding compressors are constructed from the best materials.

AGS is an established Bitumen Sprayer Blower manufacturer in India with wide experience in the industry.

AGS Vacuum blowers are an essential piece of equipment in many industrial settings. They work to enhance ait flow through the use of an electric motor, rotor and airfoils. Their purpose is to remove contaminants from the air such as dirt, dust, and move particulate matter.

AGS designed reliable units are for pumping volume of oxygen circulation. Because of high circulation rate of oxygen allow for higher feeding rates. These unit are typically selected for ponds bottom to surface aeration when a aerator gives surface aeration is neither necessary nor desire. Selection of this blower reduces energy cost, maintans & increase higher dissolved oxygen levels, low start up coast, add natural oxygen and allow to higher stocking densities. Aerator technology is replaced and discarded year after year.

AGS Ring Blowers utilize the principle of centrifugal force. Imagine a high-speed impeller spinning within a housing containing an intake and an outboard channel. As air enters the blower, the impeller's rotation creates a centrifugal force that pushes the air outwards. This air is then channeled along a precisely designed sigle channel, creating a continuous flow without the need for additional components like pistons or vanes.